We’re ready to support you. Leave us a message and we’ll get in contact.

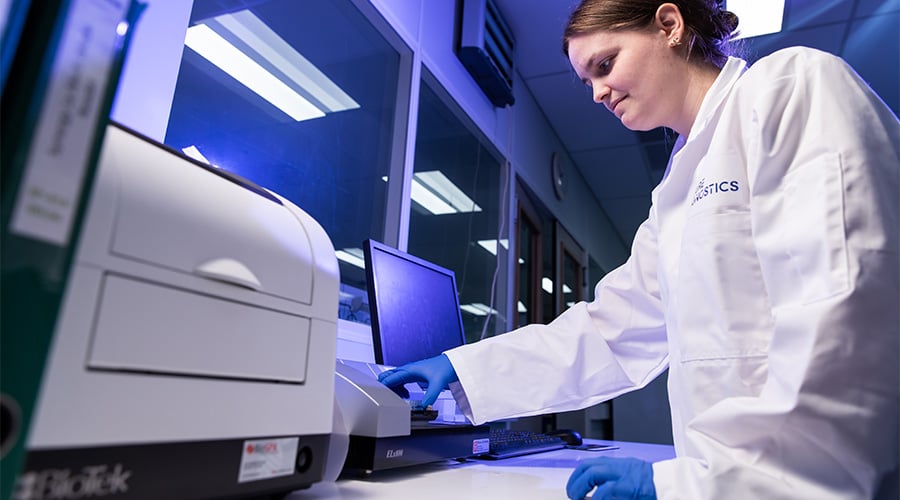

Contract manufacturing services

Accelerate your route from concept to commercial impact. As your dedicated diagnostic manufacturing partner, we deliver small-scale to medium-scale RUO and IVD (EU) kit manufacturing and high-performance reagent services with full project transparency. Our model is built for speed: ideal for pilot batches, pre-commercial runs, and confident scale-up. With ISO 13485 contract manufacturing tightly integrated with assay development, you reduce risk, shorten time-to-market, and protect quality from day one.

Why work with us

Win time, cut risk, and keep momentum. We run compact, well-documented processes for feasibility, assay optimization, verification and validation (V&V), and manufacturing. You get clear QC criteria, a complete documentation package for your Design History File (DHF), and controlled logistics with both cold chain and ambient options. With freeze-dried reagents via lyophilization and Accusphere, you unlock longer shelf life, rock-solid dosing consistency, and easier handling – translating directly into lower costs and higher reliability. Manufacturing services we offer:

- Production and assembly of full immunoassays (e.g. ELISA, EIA, CLIA) (200 – 600 kits per batch)

- Reagents production (e.g. critical components, conjugates, calibrators/controls, buffers)

- (paramagnetic) bead coating

- Lyophilization of kit components, also accuspheres

- Product filling, capping and labeling

Ready to accelerate?

Let’s discuss how we can shorten your time-to-market and strengthen product performance. Contact us for a no-obligation consultation on pilot batch manufacturing, stability studies, and scalable production strategies.

RUO kit manufacturing that accelerates your time-to-market

We take care of kitting, labeling, and fill-finish for ELISA and CLIA kit manufacturing, including vial filling and microplate filling. Expect rapid turnaround for feasibility, V&V, and pre-commercial batches during development as well as during routine manufacturing, backed by full batch documentation, established QC, and controlled shipping. The result: fewer iterations, lower technical and operational risk, and a clear, de-risked path to tech transfer to IVD and scale-up.

Quality and compliance from day one

Every project runs under an ISO 13485–certified development and manufacturing process following our recognized New Product Development Process (NPDP). We track deliverables, quality, budget, and timelines to provide full visibility — no surprises. Documentation aligns with regulatory needs and helps accelerate your market entry and downstream approvals.

Built for scale, automation, and platform integration

We design manufacturing workflows with scalability at the core — ensuring a smooth transition from small-scale pilot production to full-scale commercial manufacturing. Our processes minimize future redesigns, reduce risk, and support efficient scale-up in line with demand. Workflows operate effectively in both manual settings and automated platforms, — ready for high-throughput environments. For commercial rollout, we collaborate with trusted partners to deliver a streamlined path to market without compromising performance, consistency, or quality.

One partner for speed and certainty

By combining assay development, reagent sourcing and manufacturing services under one roof, Future Diagnostics removes friction from your roadmap. You get a single point of contact for coordination, clear deliverables with firm timelines, and predictable outcomes with full transparency. This integrated model enables smooth execution from early-stage development to batch production — accelerating your path to commercialization while reducing total cost and risk.

Ready to accelerate?

Discover how our contract manufacturing services can take your diagnostic product from pilot batches to full-scale production. Contact us for a no-obligation consultation.